Design

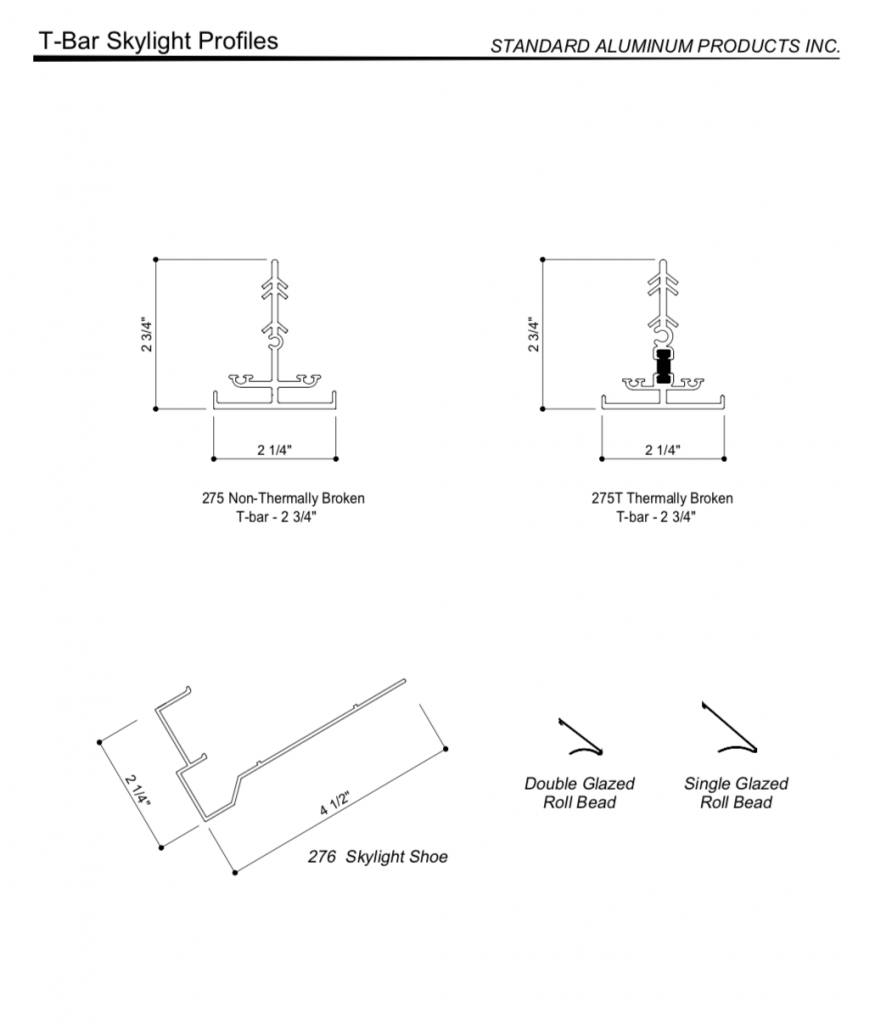

T-bar sections are available in either thermally broken for insulated sealed units or non-thermally broken profiles for single glazed application.

Glass is fixed into the T-bar with the use of a snap-in aluminum roll bead. The size is determined by glass or unit overall thickness.

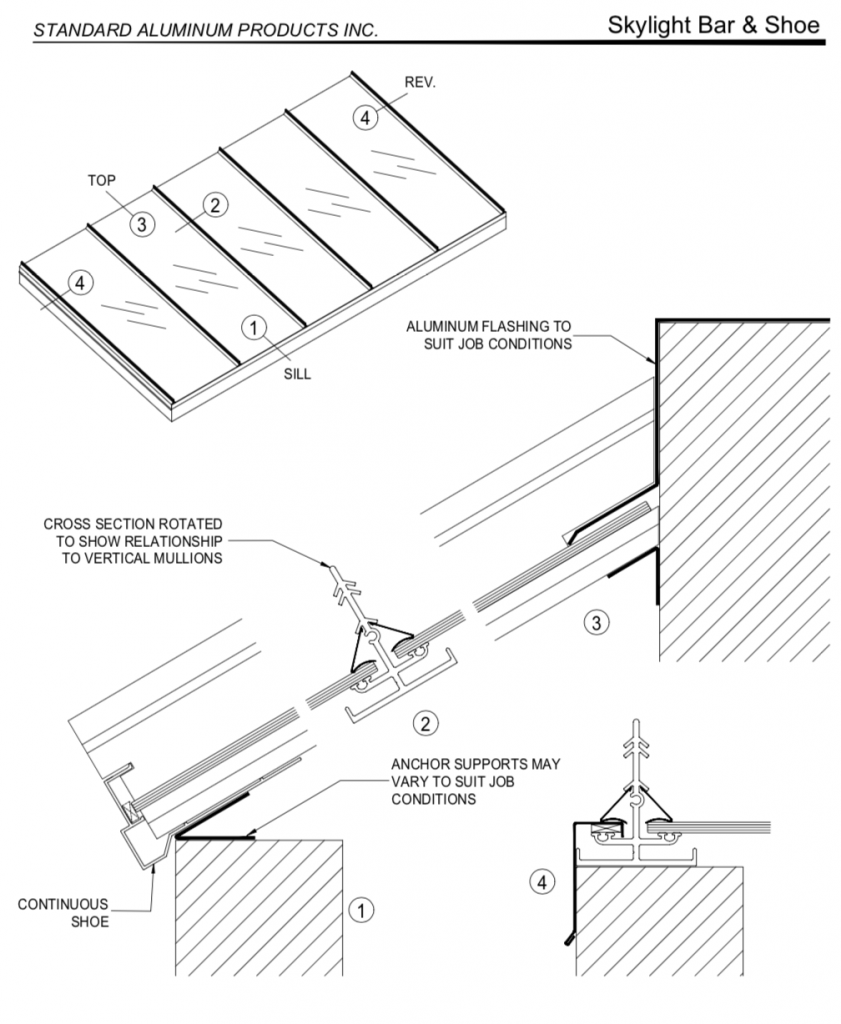

A continuous shoe extrusion acts as a glass stop and gutter, and protects the insulated unit from ultraviolet rays. The continuous shoe has a nice clean line appearance across the bottom of the skylight.

Performance

A certified engineer, to conform to local loading requirements and surrounding load criteria, should confirm all applications. The size of the T-bar extrusion is determined by the slope of skylight, and the spans and snow load requirements.

Materials

Extrusions shall be 6063 alloy and T5 temper. Glazing gaskets shall be EPDM elastomeric extrusions.

Finish

Both anodized and painted finishes are available. All integral colour anodizing is Architectural Class II, 0.4 to 0.7 mm coating. A fluropolymer paint coating to the requirements of AAMA 603 and AAMA 605 specifications is used, the industry standards toughest coating.

Protection And Cleaning

After installation the general contractor should adequately protect the exposed aluminum and glass surfaces from damage by other trades i.e. (but not restricted to) cement splash and leach, grinding, polishing compounds, plaster, paint, lime, acids and other contaminants.