General

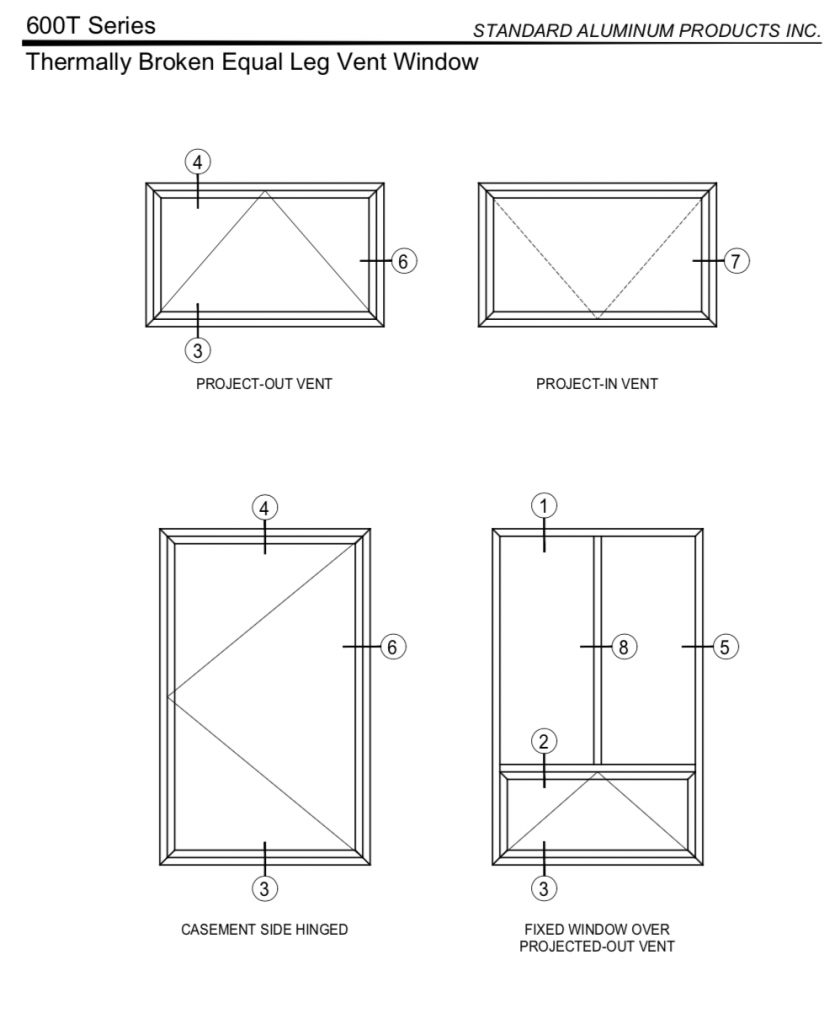

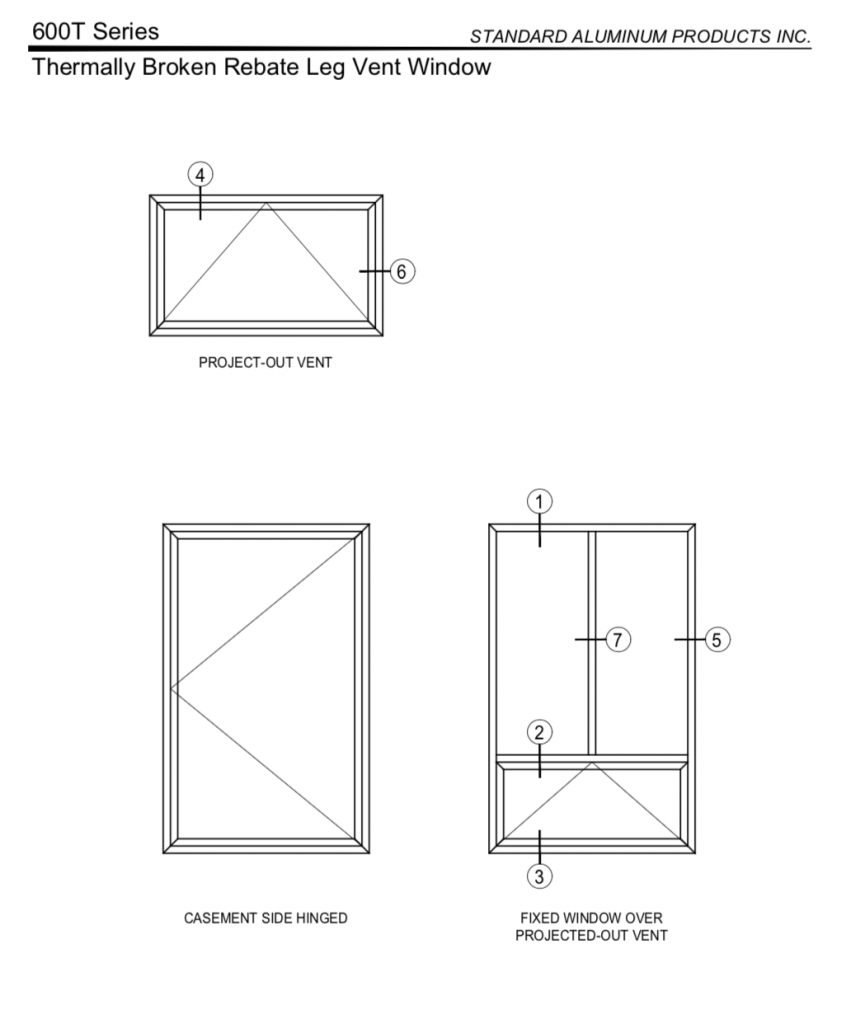

Architect to specify window type (project out or project in ventilator). Aluminum windows shall be hinged compression sealed (thermal break). Windows and accessories shall be furnished in the types and sizes indicated on the architectural drawings.

Material

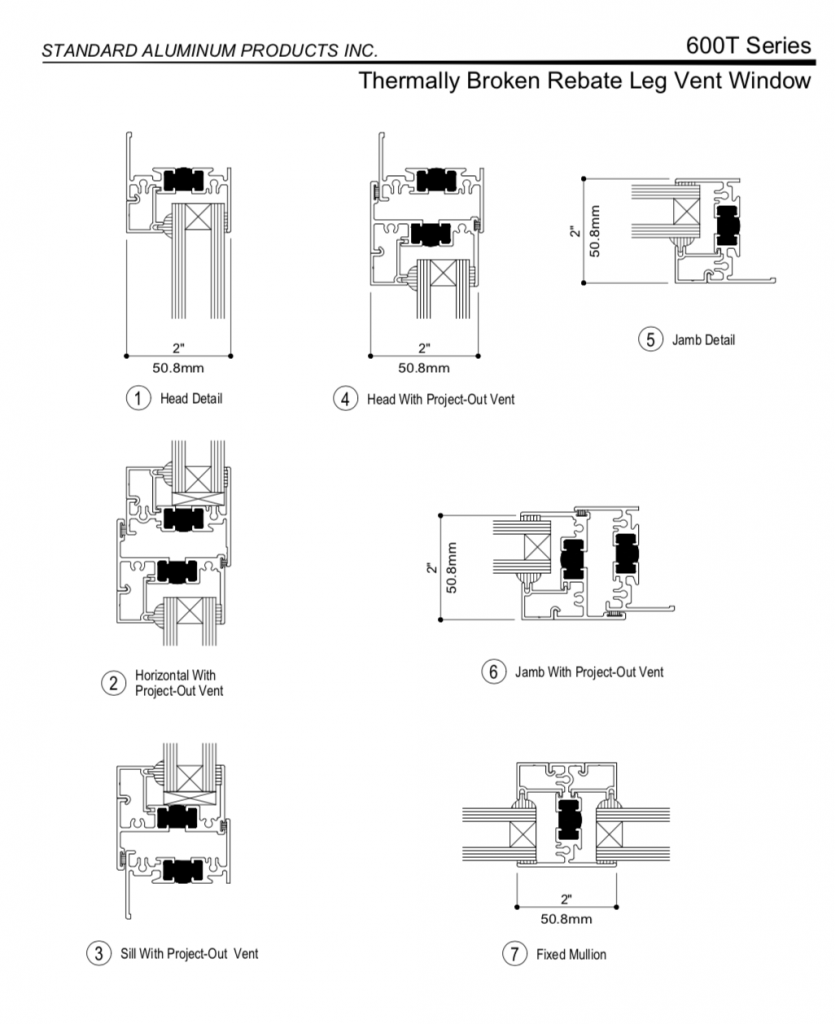

All aluminum extrusions shall be 6063-T5 or T6 alloy. The depth of frame shall not be less than 2 inches. All fasteners shall be aluminum alloy or stainless steel. Weather stripping will be shop installed in integral retaining grooves. Thermal break material shall be poured in place polyurethane.

Construction

Corner construction will be mitred and mechanically fastened. Frame and ventilator members to be one piece, continuous with no splices. All corner joinery will be shop sealed with small joint sealant.

Hardware

All opening handles shall be of die cast metal alloy. Solid bronze locking handles are also available. The hinge assembly shall be a pair of 4-bar heavy duty hinges.

Finish

Both anodized and painted finishes are available. All integral colour anodizing is Architectural Class II, 0.4 to 0.7 mil coating.

Testing

Testing requirements shall be based on CMHC specifications and CSA/CAN3 A440-M90 “windows”

Protection And Cleaning

After installation the general contractor should adequately protect the exposed aluminum and glass surfaces from damage by other trades i.e. (but not restricted to) cement splash and leach, grinding, polishing compounds, plaster, paint, lime, acids and other contaminants.